CV-120

The ConturoMatic CV120 is a classic contour-measurement device which impresses users with its intelligent features and useful automation. It offers everything that a high-performance and reliable contour measurement system should. Originally developed for the monitoring of industrial production processes, our CV120 also performs well in the measuring room, thanks to robust mechanics and powerful software. Workpieces can be automatically measured across the entire measuring range. The calibration of the entire feed unit is fully automated. High measuring accuracy, detailed evaluation, the simplest of operations as well as a superb price make the ConturoMatic CV120 particularly attractive. It is available with a stone or aluminium plate (for mobile use).

- External control via standard USB interface

- Measuring range CV120: 30 x 120 mm

- Positioning range of Z-column: 380 mm

- Software-controlled probe-arm-retraction function

- Automatic measurement via teach-in programming

- Motion of all axes can be automated

- Easy-to-change probe arm

- Calibration standard for dynamic X/Z-calibration

- Available as a mobile system with vertical X-axis for contour testing of large workpieces on the production machine (e.g. track of large bearing rings)

- Software basis of ConturoMatic: W10/64Bit, optionally W7/64Bit

CV-300

Our ConturoMatic CV300: the logical expansion of the proven principle underlying our CV120. The ConturoMatic CV300 offers, thanks to its measurement range of 100 x 300 mm, the possibility of checking contours of large and heavy workpieces. ConturoMatic CV systems are classic contour-measurement devices which stand out thanks to their intelligent features and useful automation. They offer everything that a high-performance and reliable contour measurement system should.

- External control via standard USB interface

- Measuring range CV300: 100 x 300 mm

- Positioning range of Z-column: 400 mm (optional 600 mm)

- Software-controlled probe-arm-retraction function

- Automatic measurement via teach-in programming

- Even extremely large and heavy objects can be measured

- Motion of all axes can be automated

- Easy-to-change probe arm

- Calibration standard for dynamic X/Z-calibration

- Available as a mobile system with vertical X-axis for contour testing of large workpieces on production machines (e.g. track of large bearing rings)

- Software basis of ConturoMatic: W10/64Bit, optionally W7/64Bit

TS

The geometrically unique, horizontal position of the probe arm enables the testing of contours and in holes of a diameter of under 2 mm, up to over 300 mm. Probe tip breakage is minimised through the integrated safety restriction of Z-axis movement. The possibility of roughness testing, provided by the integrated measuring force setting, can be used in combination with the contour test. Re-measuring is therefore unnecessary in many cases. Contour and roughness results can practically be determined in a single transit.

Further tasks which can be undertaken via the ConturoMatic TS include the testing of holes, distances from interior and exterior contours, threads, angle of taper, parallelism, formal errors, measurement of uninterrupted surfaces, without losing the absolute reference etc.

- Robust mechanical basis

- Large measuring range 250 x 320 mm (TS), 280 x 350 mm (TS-X)

- Guide elements made of granite. The basis for the highest of guide accuracy

- Integrated, motorised Y-variable table for automatic Zenit search (optional)

- Motor-controlled measuring axes

- Permanent, dynamic speed control. This leads to a constant data-point distance, regardless of the profile tilt

- Contactless, incremental measuring systems. Our gauges behave like steel, from a thermal perspective. Temperature compensation or time-consuming climate control is therefore often unnecessary

- Integrated control electronics

- Data acquisition and control via standard interfaces, guaranteeing future-proofing and independence from changing computer hardware

- No significant radius movement of the probe element

- Horizontal position of sensing device, which is unambiguous at all times. This enables simple, risk-free and automatic part testing

- Error limit: ± (0.9 + L/100) μm [L = measurement range in mm] (ConturoMatic TS)

- Error limit: ± (0.85 + L/100) μm [L = measurement range in mm] (ConturoMatic TS)

- Software basis of ConturoMatic: W10/64Bit, optionally W7/64Bit

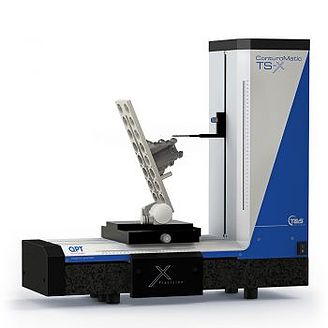

TS-X

Our proven concept: Creating “contour- and roughness-measurements of the highest level” is the constant motivation behind the further development of our systems. Under the motto: “‘Better’ is the enemy of ‘Good'” we have once again reviewed with a critical eye all those elements of the ConturoMatic TS which are crucial for the accuracy of the system. The meticulous fine-tuning of the guides, of the aerostatic air-lubricated bearings, fast data transfer, high-speed axis control, an optimised probe arm mount, re-developed drive units, as well as incremental measuring systems of the highest quality, are the results of a comprehensive process of further development.

At the end of which stands the latest achievement:

The ConturoMatic TS-X – our most powerful measuring station.

- Friction-free, aerostatic special air-lubricated bearings in the X and Z axes

- Extended measuring range X/Z (280 x 350 mm)

- Hybrid ceramic probe-arm mount

- Static probing and measurement data recording in the X direction

- Module for roughness-testing within the standard scope of delivery

- Table load capacity 25 kg (optionally up to 50 kg).

- Y-table adjustable manually and by motor

- Contactless, incremental measuring systems based on steel.

- Measuring system resolution 1 Nm

- Superior price:performance ratio

- Error limit: ± (0.85 + L/100) μm [L = measurement range in mm] (without change of probe direction)

- Combined contour- and roughness-measurement possible over the entire measuring range

- Software basis of ConturoMatic: W10/64Bit, optionally W7/64Bit

For more information see the following video: https://youtu.be/uIBs4aLYq_Y

ConturoMatic S1 evaluation software

The operating concept of the ConturoMatic S1 evaluation software is ideally suited for both production monitoring and for use in test laboratories. All contour- and roughness-measurement devices are essentially based on the profile method. Therefore, we have developed a uniform software base as the user interface.

- Evaluation functions just a click away

- Fully automatic assessments and tolerance comparisons

- Measure – Evaluate – Save

- Form and position tolerance

- Free software updates and enhancements

Accessories and options

The modular concept allows economic entry into the TS class with the option of retrofitting additional functions at any time – without mechanical intervention on the existing system, simply by software release. The optional enhancement packages contain all the necessary components, such as sensing devices for up/down probing and a roughness sensing device with a diamond tip.

- UD (Up/Down)

- Roughness

- Motorised Y-table

- Thread evaluation

- Taper thread evaluation

- Data export interface

- Roughness measurement

Profilometer Software

The comprehensive software package was designed with the user in mind. Although the software is both powerful and flexible, it retains its ‘user friendly’ appeal.

The time delay between completing a trace and evaluation of results has been kept to a minimum.

Where measurements are repeated and repetitive, within the software there is the facility to programme an automatic measuring and evaluation cycle.

Using tolerance bands, the measuring process can be performed and analyzed without operator interpretation. Allowing use by less highly skilled personnel.

A ‘master tracing’ of a component can be stored showing all required dimensions and thereafter can be used to compare against other traced components. This gives a time saving of more than 50%, especially when evaluating complex components.

The Multi Contour facility will measure two areas on the same component and also evaluate the relationship between the two areas. (Internal and External features for example).

The software uses a single click technology to each function without the need to go through menus or sub menus.

Training takes a relatively short time. Should there be a need to refresh the Trainees memory, one can refer to the straightforward unambiguous software guidance programme